Restocking a Stock from a Central Stock

It is possible to use transaction orders to restock your stocks from a central stock, using the PAR level settings defined for the stock items.

To enable this:

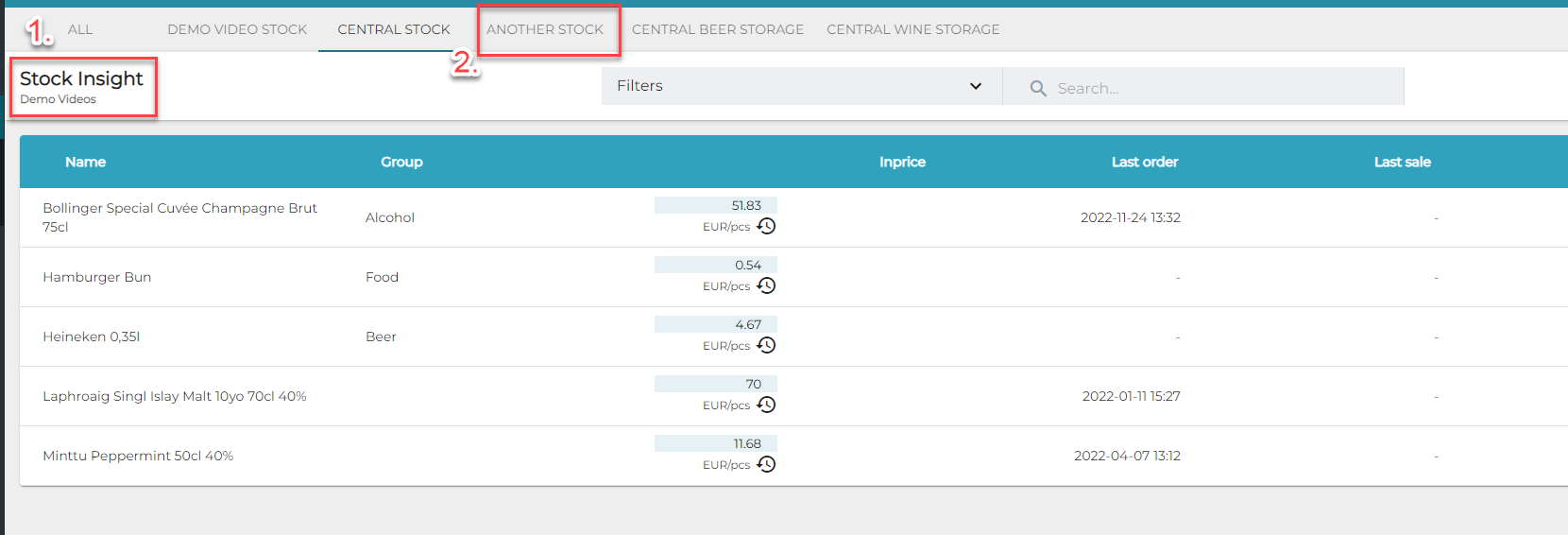

Open the Stock Insight view of your central stock.

Select the stock whose items you want to restock from the toolbar.

Stock selection visible in the central stock’s Stock Insight view

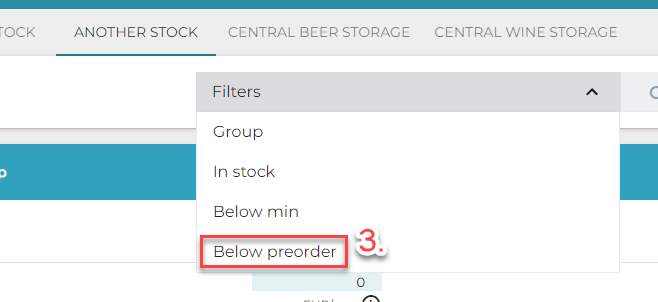

Select the Below preorder filter from the Filters drop-down menu, and click Apply filters. The filter enables you to restock your selected stock as close to MAX value as possible.

Filter selection

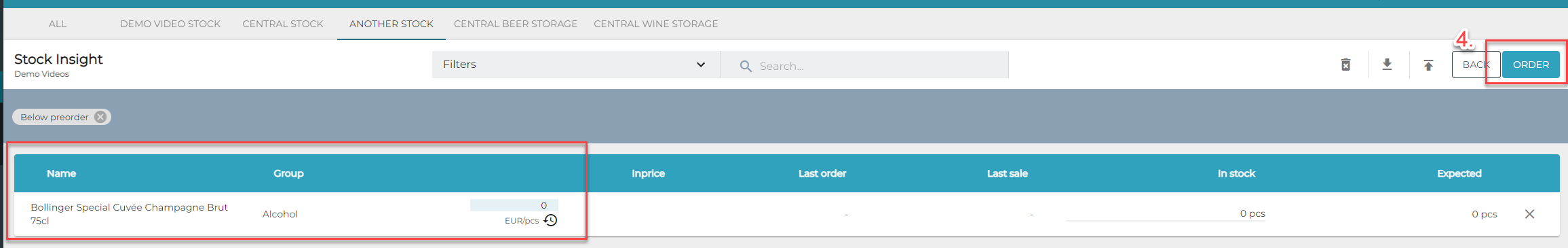

Now the stock items that need to be transferred are displayed Stock Insight. Click Order.

Stock Items to order

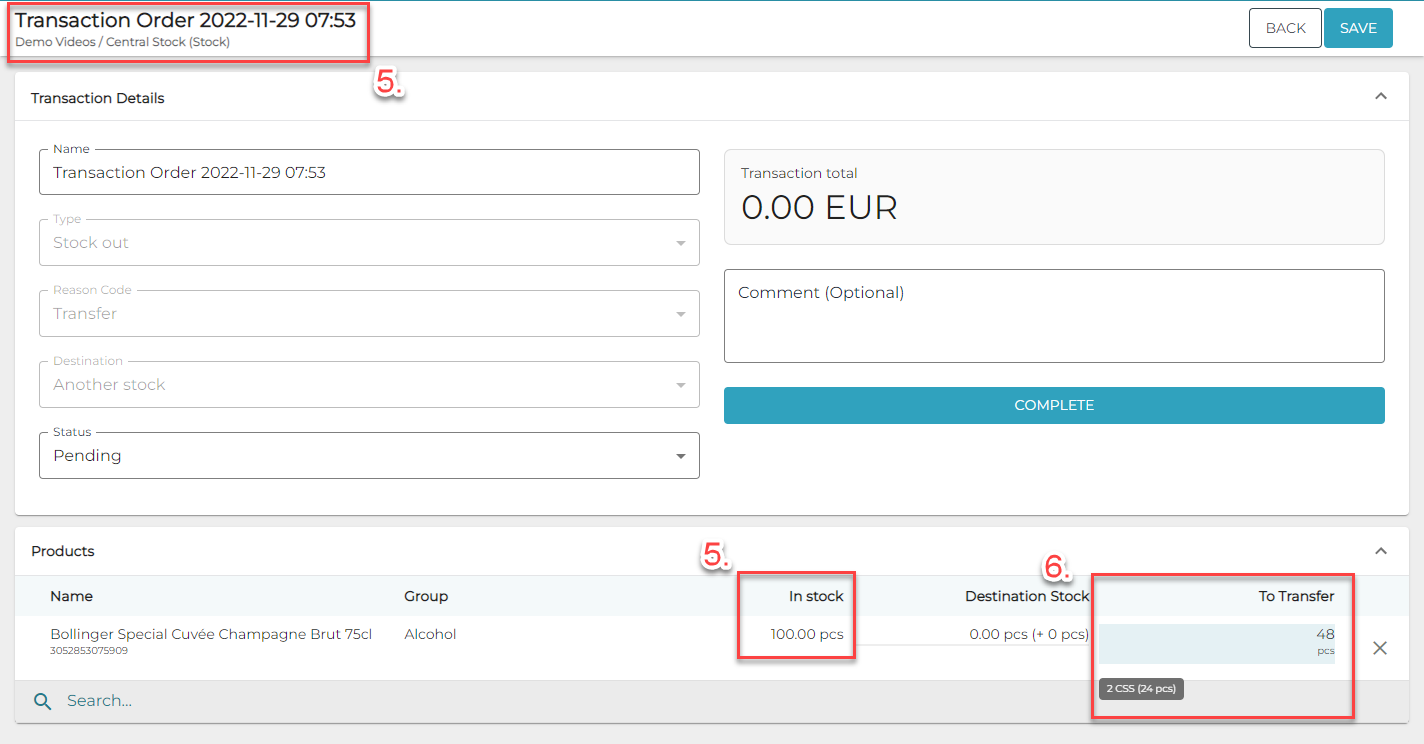

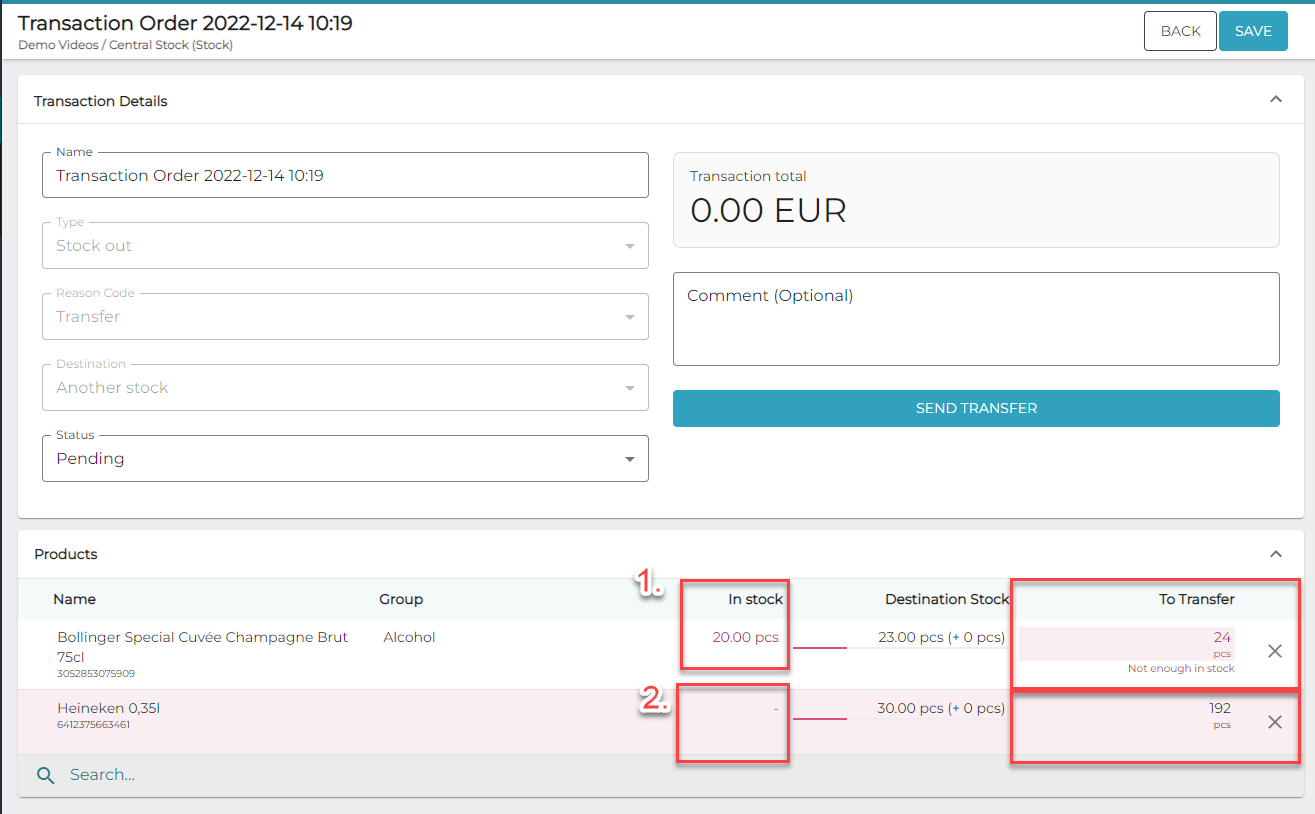

A new Stock Out transaction order with type Transfer is automatically created from the central stock, with the selected stock as the destination.

The In stock quantity of stock items currently on central stock is also displayed.

The system will calculate the optimal To Transfer quantity, based on the PAR level settings of the stock items.

To display the quantity in order units, hover the mouse cursor on the field or click it.

Prefilled transfer order

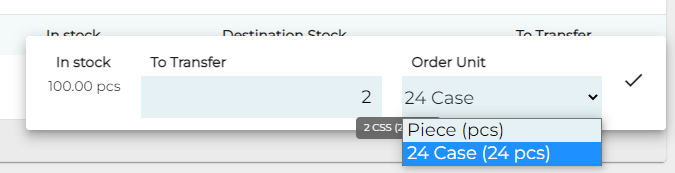

You can change the Order Unit and To Transfer quantity by clicking on the To Transfer field and entering/selecting the new values in the pop-up window.

Click Complete. This will

create a Stock Out: Transfer transaction order with Completed status on central stock,

create a Stock In: Transfer order on the destination stock, and

put the stock items in On Transit state until they are received on the destination,

deduct the stock right away from central stock and display the quantities as expected on destination stock.

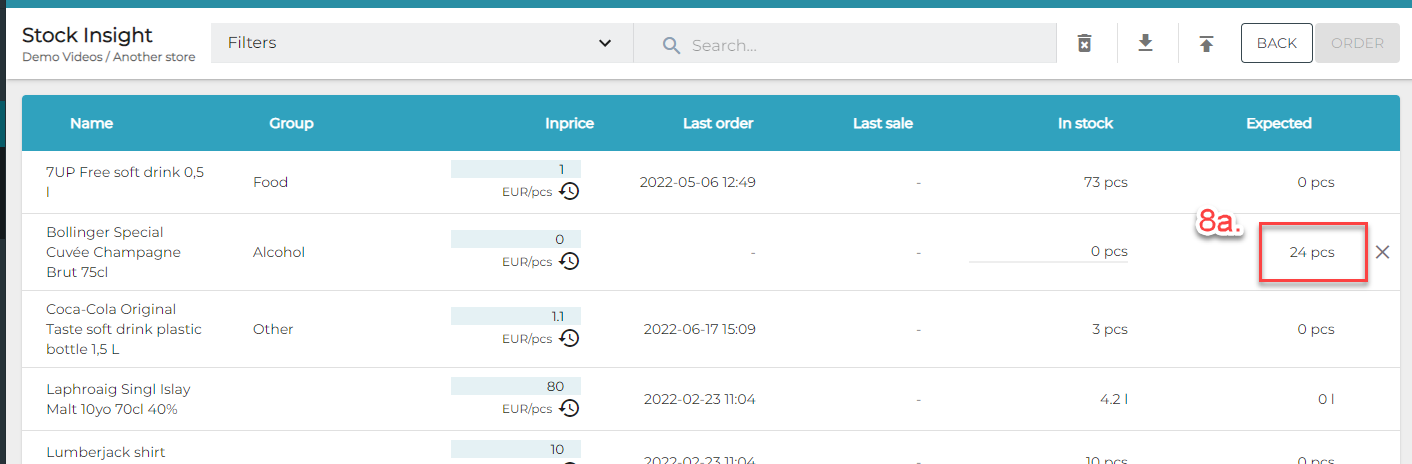

Pending Transfer In show as Expected

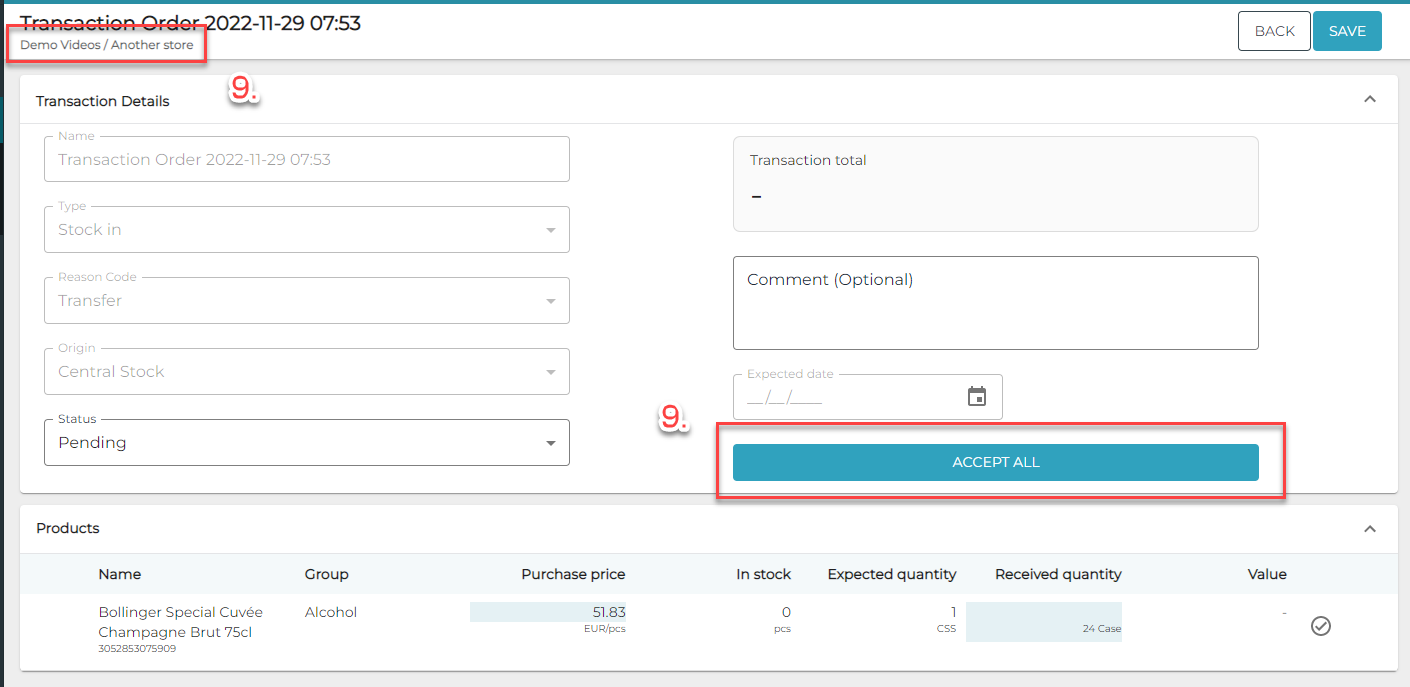

On the destination stock, the Stock In: Transfer order can now be checked and completed.

Check and accept Stock In: Transfer order

Troubleshooting

Insufficient Product Quantity in Central Stock

When creating a Stock Out: Transfer order from a central stock, the system checks the following:

whether the central stock has enough products to meet the need, and

whether the central stock has the product at all.

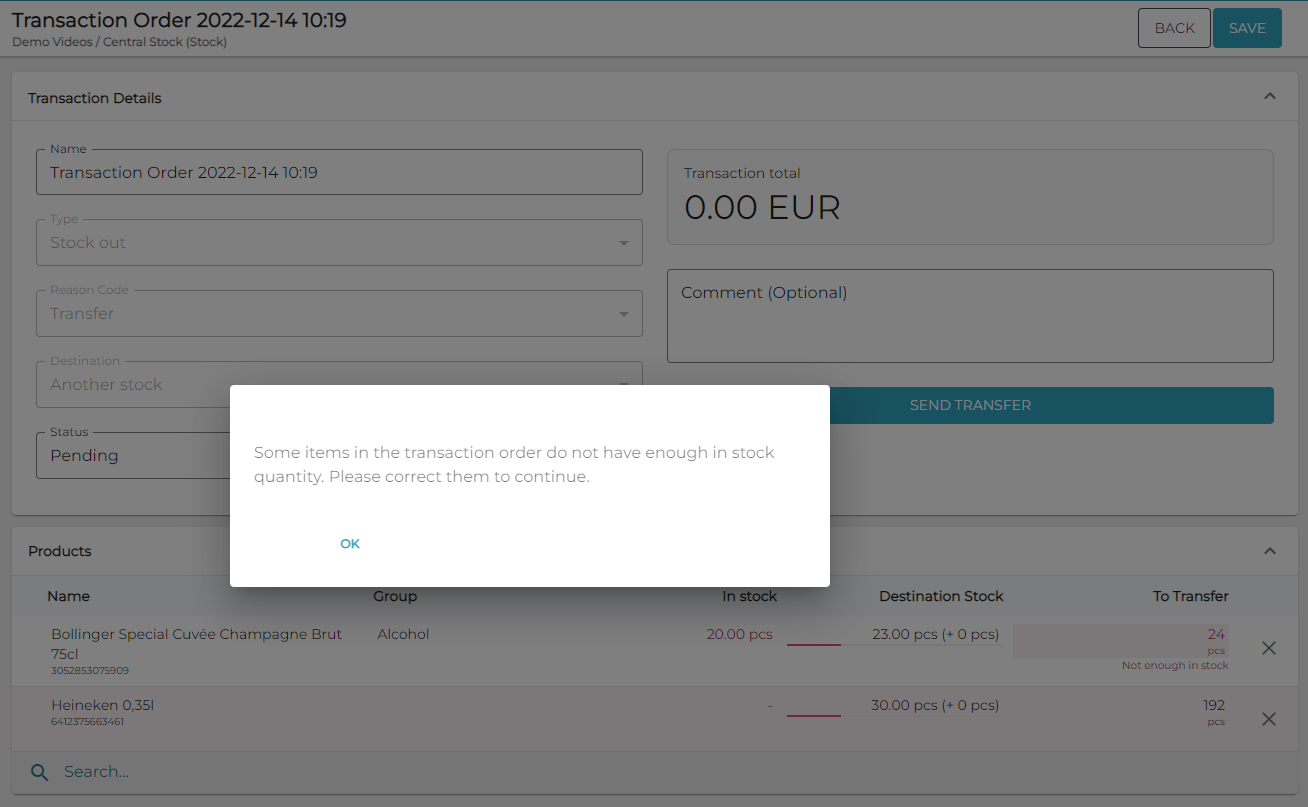

Validations for the Stock Out transfer

If the criteria above cannot be fulfilled, these problems must be corrected before the transfer can be successfully created.

Error notification: Transfer cannot be created

Expected vs. Received Quantity

How to handle the Stock In: Transfer process in cases where the user enters a different Received quantity on than was Expected:

Was some quantity of product lost during the transfer?

Create loss on destination stock for the lost amount.

It is possible to create a custom reason code for these transactions.

Was the sent quantity wrong?

Depending on whether the quantity was less or more than what was received:

Create a new Stock In or Stock Out transaction on source stock for the difference between expected vs. received quantity.

It is possible create custom reason codes for these transactions.

Change the received quantity on Stock In: Transfer order on destination stock to the correctly received quantity.